How Fashion Production Works

Fashion production is a complex process involving several phases, each of which is essential to ensure the quality and uniqueness of the final product. In this article, we will explore each phase of the process, from receiving client sketches to shipping the finished garment.

Client Sketches to Crea-Si

The first step in fashion production begins with receiving client sketches. These sketches are discussed in detail with our pattern makers to ensure that every detail of the design is understood. This phase is crucial for translating the client’s vision into a concrete fashion prototype. Pattern makers work closely with the client to refine details and ensure the initial design is respected.

Pattern making

Once the sketches are approved, the creation of the pattern begins. The pattern is a two-dimensional representation of the garment parts to be cut. This phase requires precision and technical expertise, as an accurate pattern is essential for the subsequent production phase. Our pattern makers use advanced software to create patterns that meet the exact design specifications.

3D model

If the client is interested, we offer the option to visualize the garment on a 3D avatar. This technology allows us to anticipate and correct any model issues with the fashion prototype. The 3D model allows the client to virtually see the garment worn, providing a more realistic view of how the final product will appear. This phase reduces the number of prototypes needed to achieve the final goal, subsequently reducing waste material and related time.

Prototype

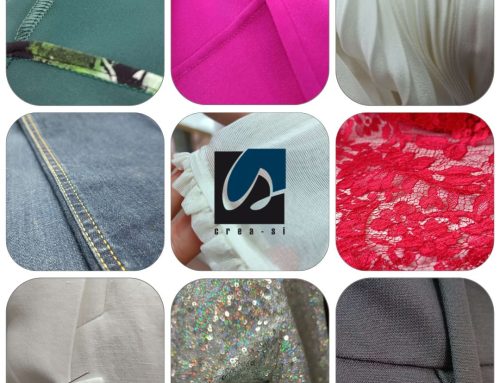

After creating the pattern and, if requested, the 3D model, we proceed to create the fashion prototype. This is the first physical sample of the garment made with chosen materials. The prototype is crucial for evaluating the design, fit, and overall quality of the garment. Any necessary changes can be made at this stage to perfect the product.

Adjustments

Fitting and defect correction are essential steps to ensure the garment is perfect before moving on to sample production. During fitting, the garment is tried on models to verify fit. Defect correction involves addressing any defects or aesthetic details that need changing before creating sample iterations. For particularly complex garments, an additional prototype may be required.

Creation of the samples

Once defect correction is complete, we proceed with sample production. The sample consists of garments identical to the prototype that will be used for the sales campaign. These garments must be impeccable as they represent the final product offered to customers.

Sales campaign

During the sales campaign, sample garments are presented to potential buyers. This phase is crucial for gathering orders and feedback from the market. A well-made sample can make a difference in the commercial success of the product.

Production

Once orders are obtained from the sales campaign, actual production begins. This phase includes several detailed steps to ensure each garment is produced according to required quality standards.

-

Size grading

Size developments are a complex and delicate process requiring a combination of technical skills, market knowledge, and attention to detail to ensure each garment produced is of high quality, regardless of size. During size developments, each size is meticulously adapted to body proportions, taking into account anatomical differences between various sizes. Pattern makers use advanced software and precise techniques to modify the original pattern, ensuring all garment elements – from seams to decorative details – are correctly proportioned. Additionally, size developments must consider target market needs and customer preferences. For example, in some markets, creating plus-size or petite sizes may require additional specific adjustments. This phase is therefore crucial to ensure the garment is accessible and suitable for a wide range of consumers, while maintaining aesthetic and functional design consistency.

-

Placement

Piazzati is a fundamental phase in fashion production, where pattern pieces are strategically arranged on fabric to optimize cutting and minimize waste. This operation requires meticulous attention and great technical expertise, as good arrangement can significantly influence production costs and the quality of the final product.

An effective placement takes into account various factors such as fabric direction, texture, and any patterns or designs that need to match perfectly. Furthermore, correct placement of pattern pieces can enhance the quality of the final product. Careful arrangement can ensure that the most visible parts of the garment, such as the front and back, are cut from the best parts of the fabric, avoiding defects and imperfections. This is particularly important for fabrics with specific patterns or textures, where a placement error could compromise the garment’s aesthetics.

Optimizing placement also requires the use of advanced software that helps pattern makers simulate various arrangements and choose the most efficient one.

-

Cutting

The cutting process requires meticulous attention to detail. Even a small error can compromise the entire product, causing alignment and fit issues. Therefore, industry professionals use advanced cutting tools such as industrial cutters, laser cutters, and automatic cutting machines. These tools not only increase cutting precision but also improve process efficiency, reducing the time required to cut fabric pieces.

Before cutting begins, the fabric is laid out and inspected to ensure there are no defects or folds that could affect cutting precision. The fabric is then secured to prevent unwanted movement during the process. Pattern makers and cutting operators must pay particular attention to fabric grain direction and pattern piece orientation to maintain design and fabric property consistency. Cutting involves not only size accuracy but also quality of the cut edge. A clean and precise edge is essential to facilitate subsequent sewing and assembly stages, reducing the risk of fraying and improving garment durability.

-

Manufacturing

Packaging is one of the crucial and artisanal phases in fashion production, where cut pieces are meticulously assembled to create the desired final garment. This process is not simply about joining pieces but includes a series of operations that significantly contribute to the aesthetic appearance and durability of the garment.

During packaging, professional pattern makers and tailors focus on seams, which must be executed precisely to ensure the garment is durable and comfortable to wear. Seams not only join fabric pieces but also contribute to the overall aesthetic of the garment, influencing how well the garment fits the body and its resistance to wear over time. Well-executed packaging not only enhances the aesthetic presentation of the garment but also its durability and customer satisfaction. Well-packaged garments better withstand daily use and maintain their shape and appearance over time, thus representing added value for the end consumer.

-

Quality Control

Before garments are ready for shipment to customers, it is essential that each individual piece undergoes a rigorous quality control process. This critical phase ensures that every detail of the garment meets the high quality standards established by the company and is free from any defect that could compromise the customer’s experience. Only after successfully passing this process are garments considered ready for shipment to the customer. This attention to detail and quality is essential to maintain the integrity of the brand and customer satisfaction, ensuring that every garment that leaves production is a reflection of the commitment to excellence and quality.

Fashion production is a detailed process that requires expertise, precision, and attention to detail at every stage. From fashion prototype to sample and through to final production, each step is crucial to ensuring a high-quality product that meets customer expectations.